Assemblies

PCX Aerosystems manufactures custom flight-critical subsystems and components for customers in the aerospace and defense sectors. We excel at developing and applying advanced manufacturing solutions to help our customers solve highly complex technical challenges. In the spirit of continuous improvement, the team at PCX Aerosystems constantly reviews the latest advances in manufacturing techniques and materials to ensure we provide the most advanced offerings and capabilities available for our customers.

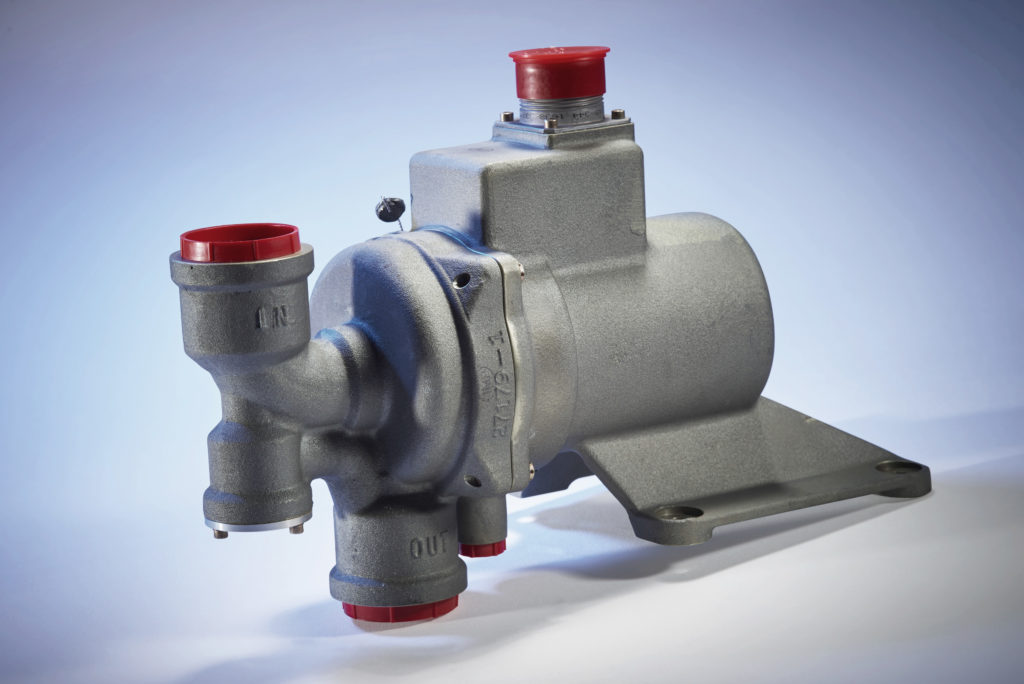

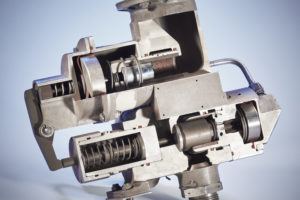

As a vertically integrated manufacturer, PCX Aerosystems excels in the production of complex metallic and composite assemblies for customers in the aerospace industry.

Assembly Capabilities

When you work with PCX Aerosystems for your assembly needs, our team brings extensive experience in aerospace industry preferences and standards to the table. We have more than 60 years of experience with complex metallic fabrication and assembly experience, as well as extensive composite assembly experience. We’ve worked directly with Tier 1 Defense Contractors such as Boeing, Lockheed Martin, Northrop Grumman, and the U.S. Department of Defense for decades.

We can build a comprehensive array of assemblies, such as:

- Landing gear components and assemblies

- Aerospace fuel and hydraulic systems

- Actuation systems

- Shock strut assemblies

- Drag beam assemblies

Our extensive portfolio allows to produce metal and composite components for these assemblies in house. These capabilities include:

- Assembly fixture design/fabrication

- Bending

- Compression molded components

- Cutting

- Design for Manufacturability (DFM)

- Forming

- Hand tooling

- High-temperature composites

- Honing

- In-house tooling

- Labeling

- Maintenance, repair, and overhaul (MRO) support

- Metallic weldment, fabrication, and routing

- Secondary bonded structures

- Tapping

- Test fixturing

Our standard tolerance range is within 0.005 inches, allowing us to create highly precise components for assembly. We prioritize quality, trust, and technical competence on every project, allowing our customers to focus on their own core competencies while we handle the manufacture and assembly of complex aerospace assemblies.

Secondary Services & Inspection

Aside from our primary fabrication and assembly capabilities, we also offer numerous secondary finishing services. These value-added processes and services allow us to offer end-to-end, single-source manufacturing on most projects:

- Anodizing

- Deburring

- Painting

- Polishing

Our quality inspections are second-to-none in our industry. Our list of inspection capabilities includes:

- Coordinate measuring machines (CMMs)

- Functional testing

- Hydraulic testing

- Mechanical inspections

- NDT inspections

- Pressure testing

- System testing