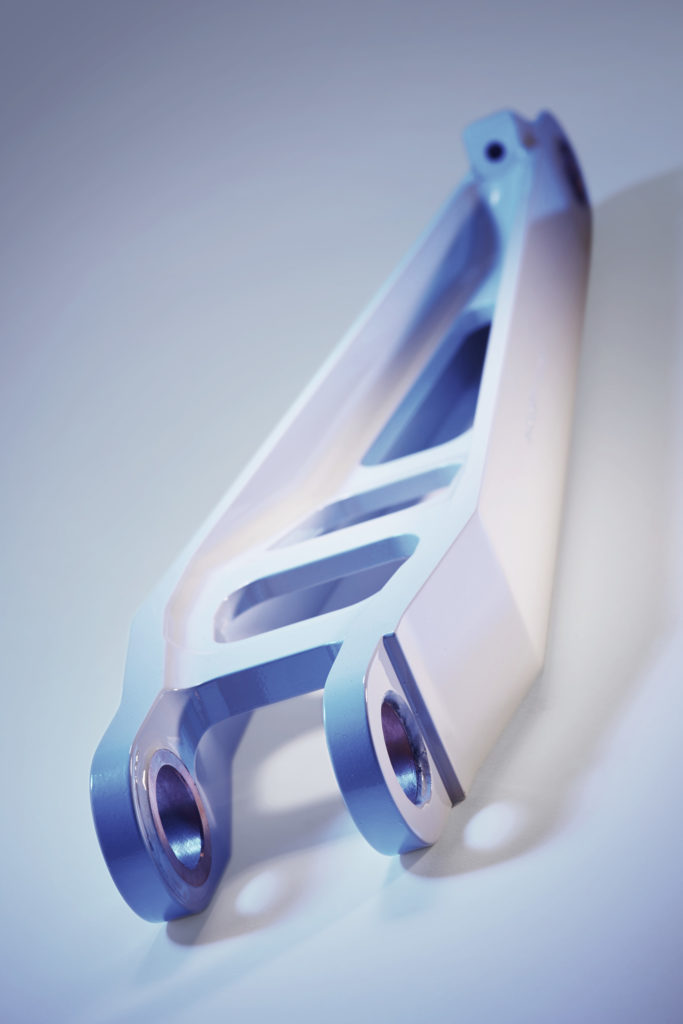

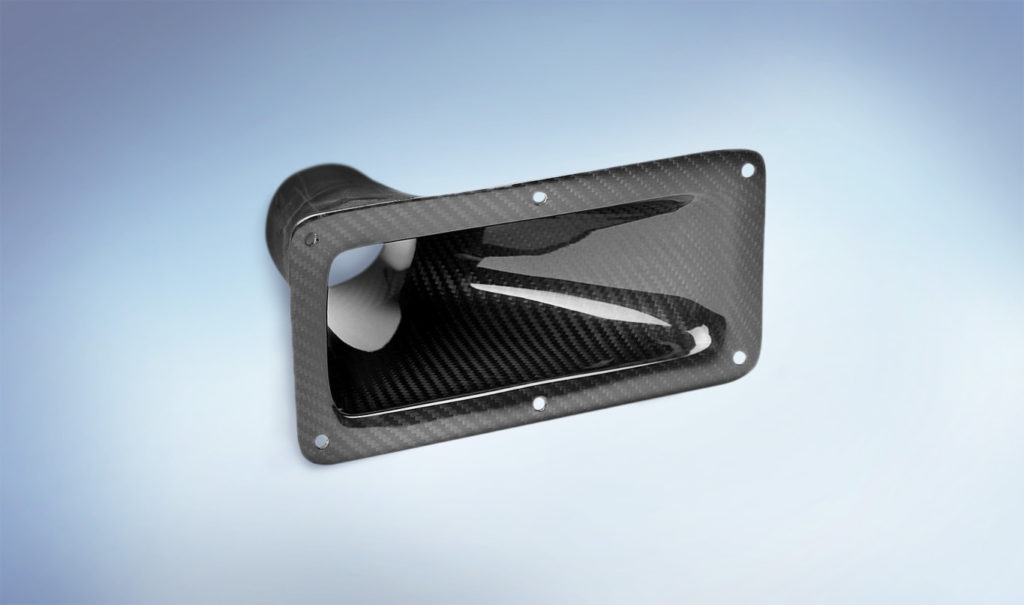

Metal & Composite Machining

PCX Aerosystems manufactures custom flight-critical subsystems and components for customers in the aerospace and defense sectors. We excel at developing and applying advanced manufacturing solutions to help our customers solve highly complex technical challenges. In the spirit of continuous improvement, the team at PCX Aerosystems constantly reviews the latest advances in manufacturing techniques and materials to ensure we provide the most advanced offerings and capabilities available for our customers.

As a vertically integrated manufacturer specializing in aerospace manufacturing, PCX Aerosystems excels in machining a broad range of composite and metallic materials.

Metal & Composite Machining Capabilities

We offer extensive experience with composite machining, supported by more than 60 years of experience with metal machining and fabrication. For decades, we’ve provided precision-machined parts to major OEMs such as Boeing, Lockheed Martin, Northrop Grumman, Sikorsky, Airbus, and more. We work with virtually all metal and composite materials, including high-temperature composites and metallic composite structures.

We use our comprehensive machining and in-house tooling design and fabrication capabilities to produce solutions for OEMs that are ready straight out of the box. We have a broad portfolio of machining equipment, including:

- CNC mills

- CNC lathes

- Filament winders

- Compression molders

- Autoclaves

- Curing ovens

Our state-of-the-art equipment grants us a variety of fabrication capabilities, such as:

- Metallic component welding, fabrication, routing, and assembly

- Composite and metallic machining

- Honeycomb machining

- CNC drilling and milling

- CNC machining and routing

- Filament winding

We can handle virtually any metal or composite aerospace component, but here are some of the most common components created in our facility:

- Duct assemblies

- Nacelles

- Plenums

- Exhaust components

- Structures

- Radomes

- Faring

- Nose cones

We can produce machined components in volumes ranging from 20-1,000 per year with lead times of 12-36 weeks. Our advanced capabilities and one-on-one customer service allow to provide faster turnarounds and higher-quality final components than our competitors.