Composites

PCX Aerosystems manufactures custom flight-critical subsystems and components for customers in the aerospace and defense sectors. We excel at developing and applying advanced manufacturing solutions to help our customers solve highly complex technical challenges. In the spirit of continuous improvement, the team at PCX Aerosystems constantly reviews the latest advances in manufacturing techniques and materials to ensure we provide the most advanced offerings and capabilities available for our customers.

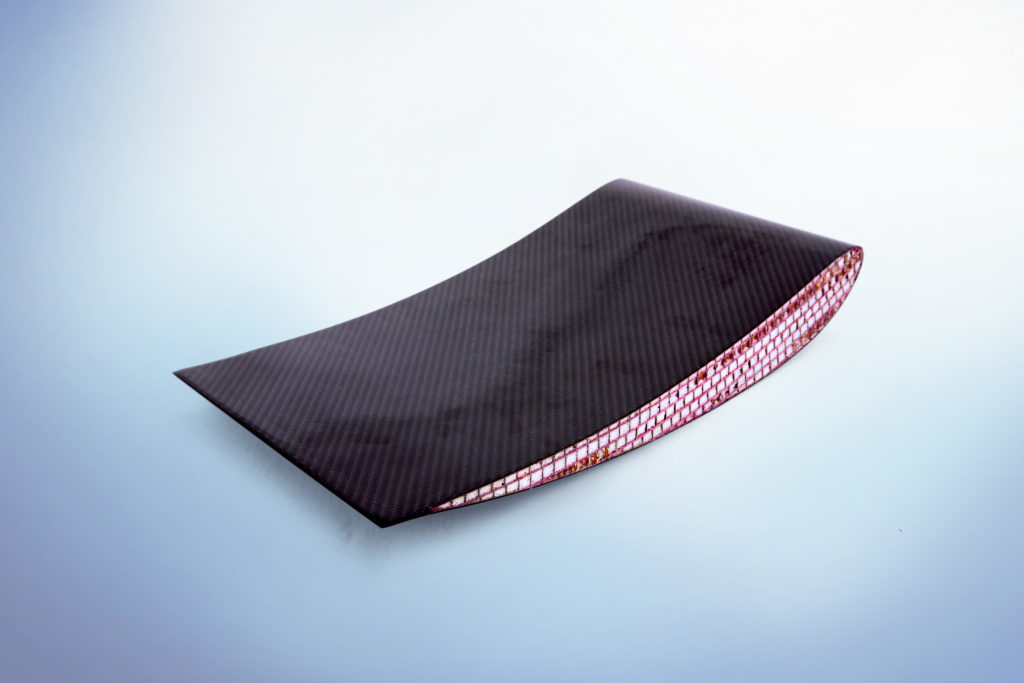

Composites join multiple materials with different properties together to create a single material that is stronger and offers better performance. Composite materials have become increasingly popular in aerospace and military applications for their favorable strength-to-weight ratio and many customizable resistances.

Our Composites Production Capabilities

At PCX Aerosystems, our teams possess a diverse range of knowledge and experience with aerospace composites. Our composite lay-up manufacturing equipment and capabilities include the following:

- 2 cleanrooms, both certified to ISO 14644-1 Class 8/FED-STD-209 Class 100,000 conditions

- Wet or dry filament winding (Winder 1: 36” diameter x 22’ length, 3-axis; Winder 2: 36” diameter x 25’ length, 5-axis)

- Autoclave: 6’ diameter x 8’ length

- Four Ovens: 8’ width x 7’ height x 29.5’ length

- Automated ply cutter

- In-house tool design and fabrication

- Composite part system integration

- Manufacturing process development

- Materials lab testing (physical, chemical, and mechanical testing)

- Advanced materials research and development

Our in-house experts specialize in high-complexity research and development, and our engineering group and technicians operate with agility that larger companies simply cannot offer. We also offer secondary services in-house, such as coating and painting, to help our customers simplify their vendor management.

We’ve worked directly with major global aerospace brands such as Boeing, GE Aviation, HITCO Carbon Composites, Lockheed Martin, Northrup Grumman, Rolls Royce, United Technologies Corporation, Zodiac Aerospace, and many others. We strive to build long-lasting relationships with our partners built on the superior service and long-term experience our team brings to the table.

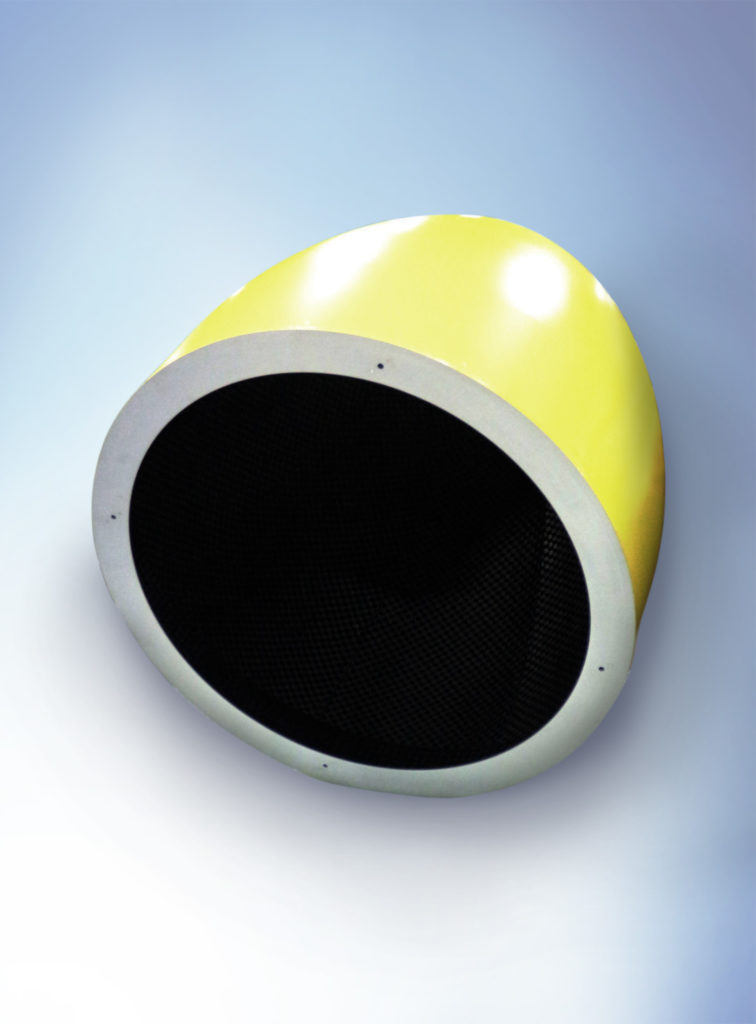

Some of the components we frequently produce for aerospace and defense applications include:

- Access doors

- External fuel tanks

- Composite overwrapped pressurized vessels (COPVs)

- Covers

- Cowlings

- Domes

- Ducts

- Fins

- Manifolds

- Missile casings

- Plenums

- Polymer matrix composites (BMI and polyimide)

- Ceramic matrix composites (oxide/oxide and carbon/carbon)